Teflon Parts are among the plastic machining parts we produce using a CNC machining process at PlaSteel. As our customers know, we are well versed in the behaviors exhibited by various plastics as they are machined. This is one of the reasons why metal machine shops, for the most part, want very little to do with plastics. Teflon is a primary culprit and there are a host of reasons why. It has a very high thermal expansion rate and hypersensitivity to heat while processing. High tolerance parts can go from “in-tolerance” to “out-of-tolerance” if too much of our hot/dry Arizona air makes its way into the inspection room. Having said that, Teflon’s properties remain at a useful level over a great temperature range (-400 to 500 degrees F)

Some of the primary characteristics of Teflon (PTFE):

- Inertness to most chemicals

- Resistance to high temperatures

- Low coefficient of friction

- Excellent dielectric properties (see below)

- Relatively insensitive to temperature

- Relatively insensitive to power frequency

- ZERO moisture absorption

- Excellent radiation resistance

PTFE (Teflon) has excellent dielectric properties. This is especially true at high radio frequencies, making it suitable for use as an insulator in cables and connector assemblies and as a material for printed circuit boards used at microwave frequencies. (see cable insulator part photos below)

Common uses for TEFLON that the average Joe would be familiar with:

- Thread seal tape in plumbing applications.

- Certain types of hardened, armor-piercing bullets, so as to prevent the increased wear on the firearm’s rifling that would result from the harder projectile.

- PTFE membrane filters are among the most efficient used in industrial air filtration applications.

- Gore-Tex is a material incorporating a fluoropolymer membrane with micropores.

- The roof of the Hubert H. Humphrey Metrodome in Minneapolis, USA, is one of the largest applications of PTFE coatings, using 20 acres of the material in a double-layered, white dome, made with PTFE-coated with a substantial use of PTFE coatings.

- Carpets using Dupont stainmaster are coated with Teflon which gives them their resistance to stains.

- Gecko’s cannot stick to teflon (we haven’t tested this yet)

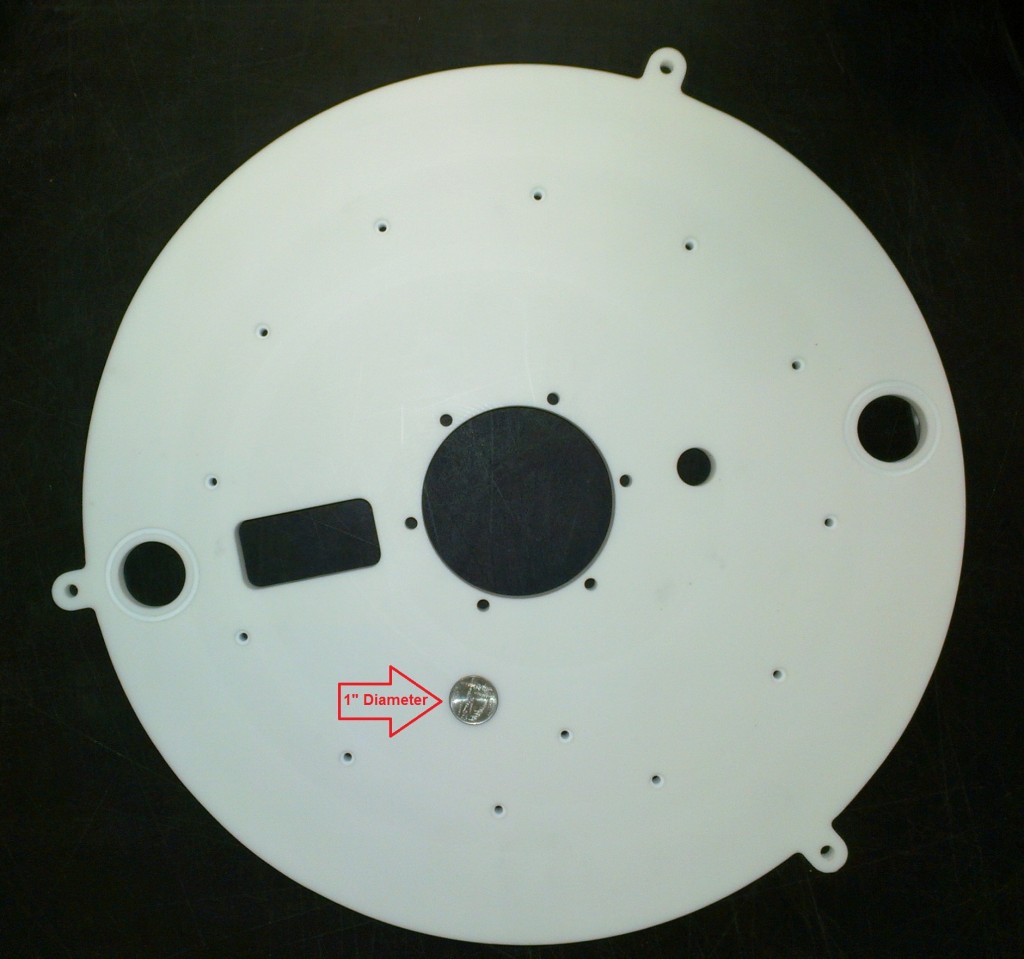

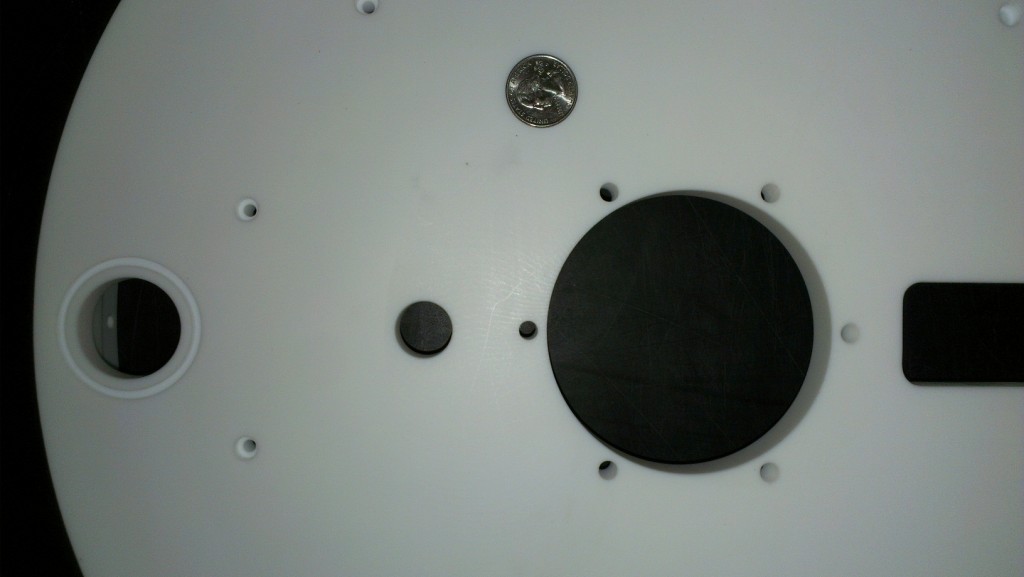

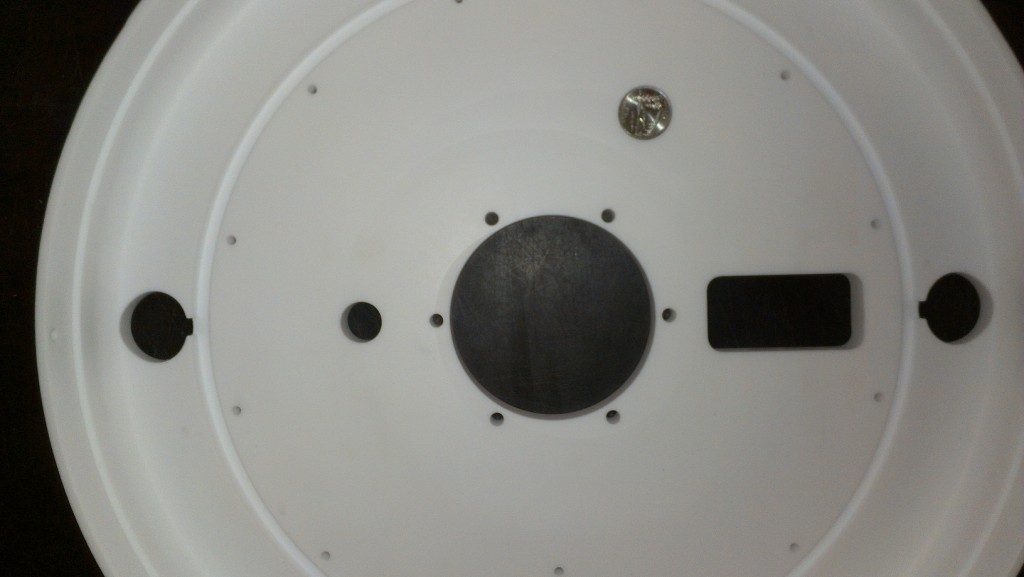

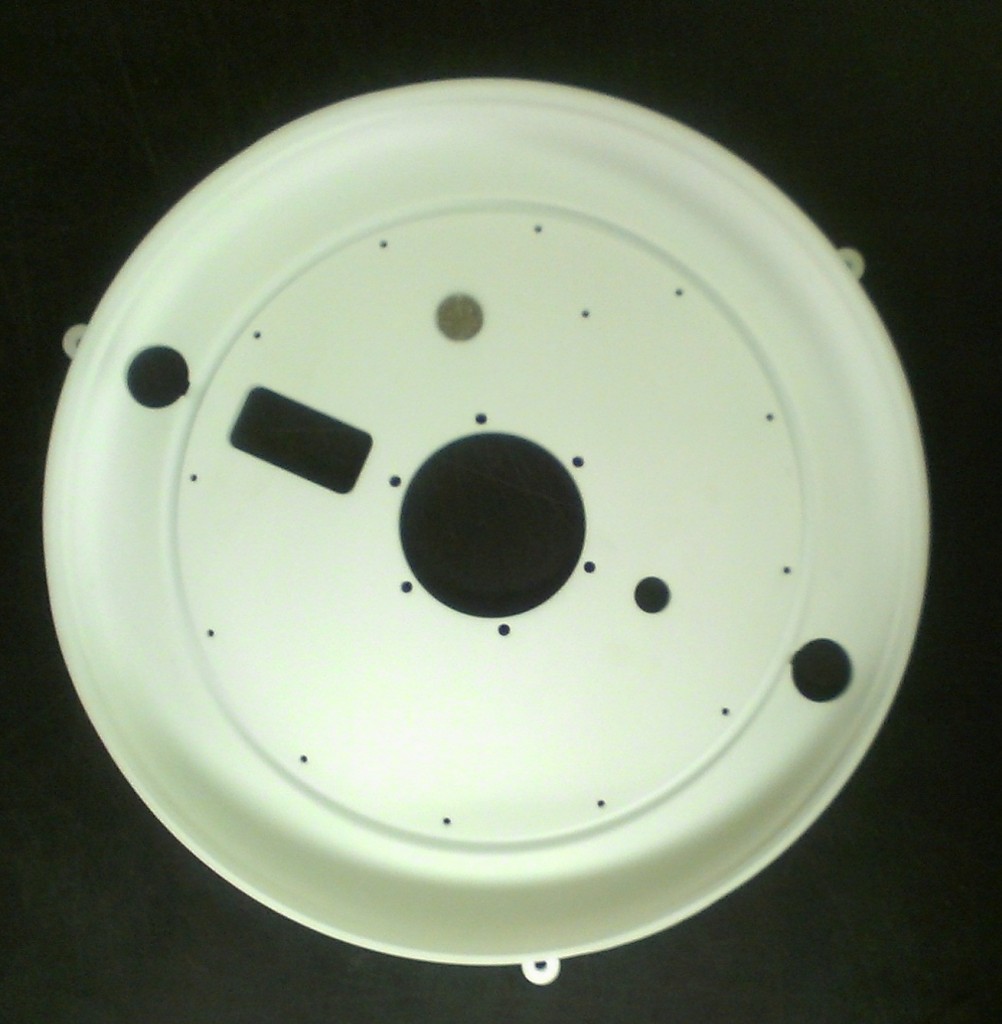

We recently produced high precision CNC machining Teflon Parts of above average size here in our Tempe, AZ facility. These parts are used during semiconductor wafer processing and their primary function is to drain noxious chemicals away from the processing area.

It is difficult to tell in the photo that there is a slope from the center outward to assist with drainage

Total overall height is about 3″

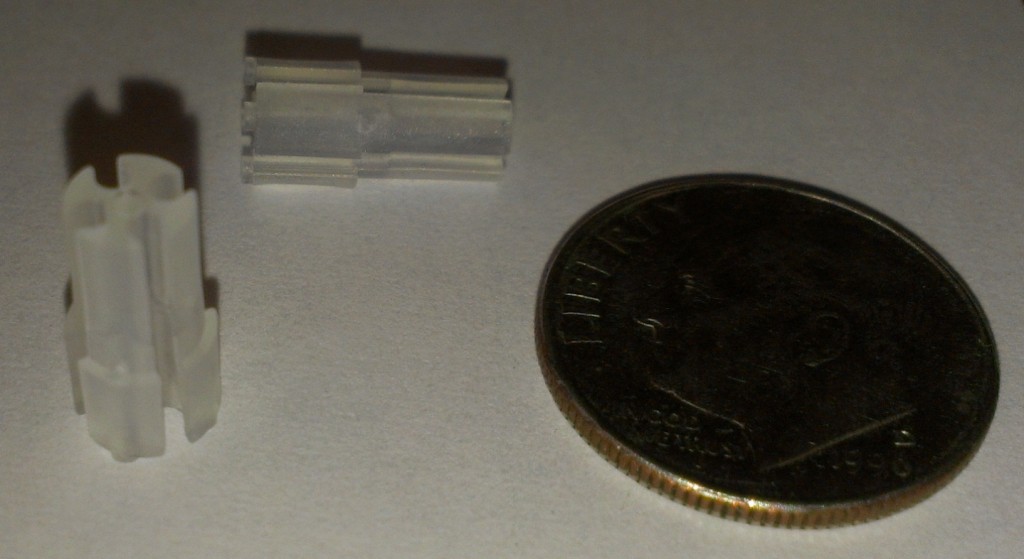

By contrast we also recently produced some of the smallest Teflon Parts to come out of our shop. They are extremely high tolerance parts with some areas needing +- .001″. This is not easy to accomplish with Teflon in a part this size. These parts are cable insulators for the aerospace industry.

Customers that select PlaSteel for their Teflon Parts rarely go anywhere else to have these parts made. Our experience and understanding of this material makes us uniquely qualified to create whatever parts you may need. Look to PlaSteel for plastic machining, or CNC machining of the teflon parts you need.

Please give our friendly sales team a call and let us know what we can do to help you.

Cheers –