Drops & Non-Certified Materials

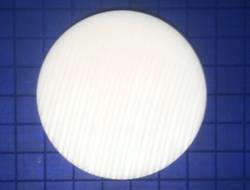

If you are currently in the prototype phase of your project and not sure what material should be selected or stage that material certification is not required. Let PlaSteel recycle program benefit you. PlaSteel routinely works with drops from high performance plastics that enter into our recycle “green” initiatives. Let us assist in cost reductions by supplying a non-certified material. We typically see a 35%-50% reduction in price. This quarter featured material:  Ultem 1000 Technical Property Data Ultem* l000 polyetherimide is an amorphous, high-performance polymer with exceptional flame and heat resistance. It performs continuously to 340°F (171°C), making it ideal for high strength/high heat applications, and those requiring consistent dielectric properties over a wide frequency range. It is hydrolysis resistant, highly resistant to acidic solutions and capable of withstanding multiple autoclaving cycles. Ultem 100 is FDA and USP Class VI compliant. FDA compliant colors of Ultem are also available on a custom basis. Ultem commonly is machined into parts for reusable medical devices, analytical instrumentation, electrical/electronic insulators and a variety of structural components requiring high strength and rigidity at elevated temperatures.

Ultem 1000 Technical Property Data Ultem* l000 polyetherimide is an amorphous, high-performance polymer with exceptional flame and heat resistance. It performs continuously to 340°F (171°C), making it ideal for high strength/high heat applications, and those requiring consistent dielectric properties over a wide frequency range. It is hydrolysis resistant, highly resistant to acidic solutions and capable of withstanding multiple autoclaving cycles. Ultem 100 is FDA and USP Class VI compliant. FDA compliant colors of Ultem are also available on a custom basis. Ultem commonly is machined into parts for reusable medical devices, analytical instrumentation, electrical/electronic insulators and a variety of structural components requiring high strength and rigidity at elevated temperatures.

| Physical Properties | Metric | English | Comments |

|---|---|---|---|

| Density | 1.28 g/cc | 0.0462 lb/in³ | ASTM D792 |

| Water Absorption | 0.25 % | 0.25 % | 24 hour immersion; ASTM D570 |

| Moisture Absorption at Equilibrium | 0.2 % | 0.2 % | Water Vapor Regained |

| Water Absorption at Saturation | 1.25 % | 1.25 % | Immersion; ASTM D570 |

| Outgassing – Total Mass Loss | 0.4 % | 0.4 % | |

| Collected Volatile Condensable Material | 0 % | 0 % | |

| Chemical Properties | Metric | English | Comments |

| Ionic Impurities – Na (Sodium) | 6.4 ppm | 6.4 ppm | |

| Ionic Impurities – K (Potassium) | 0.1 ppm | 0.1 ppm | |

| Ionic Impurities – Fe (Iron) | 0.7 ppm | 0.7 ppm | |

| Mechanical Properties | Metric | English | Comments |

| Hardness, Rockwell M | 112 | 112 | ASTM D785 |

| Hardness, Rockwell R | 125 | 125 | ASTM D785 |

| Hardness, Shore D | 86 | 86 | ASTM D2240 |

| Tensile Strength, Ultimate | 114 MPa | 16500 psi | ASTM D638 |

| Elongation at Break | 80 % | 80 % | ASTM D638 |

| Tensile Modulus | 3.45 GPa | 500 ksi | ASTM D638 |

| Flexural Modulus | 3.45 GPa | 500 ksi | ASTM D790 |

| Flexural Yield Strength | 138 MPa | 20000 psi | ASTM D790 |

| Compressive Yield Strength | 152 MPa | 22000 psi | 10% Deflection; ASTM D695 |

| Machinability | 30 % | 30 % | QEPP 10 to 100 scale |

| Shear Strength | 103 MPa | 15000 psi | ASTM D732 |

| Compressive Modulus | 3.31 GPa | 480 ksi | ASTM D695 |

| Coefficient of Friction | 0.42 | 0.42 | Dynamic; Dry vs. Steel; PTM55007 |

| K (wear) Factor | 2900 | 2900 | 10-10 in3-min/lb-ft-hr; PTM55007 |

| Limiting Pressure Velocity | 0.0657 MPa-m/sec | 1875 psi-ft/min | PTM55007 |

| Izod Impact, Notched | 0.267 J/cm | 0.5 ft-lb/in | ASTM D256A |

| Electrical Properties | Metric | English | Comments |

| Surface Resistivity per Square | Min 1e+013 ohm | Min 1e+013 ohm | EOS/ESD S11.11 |

| Dielectric Constant | 3.15 | 3.15 | 1 MHz; ASTM D150(2) |

| Dielectric Strength | 32.7 kV/mm | 830 V/mil | Short Term; ASTM D149(2) |

| Dissipation Factor | 0.0013 | 0.0013 | 1 MHz; ASTM D150(2) |

| Thermal Properties | Metric | English | Comments |

| CTE, linear 68°F | 55.8 µm/m-°C | 31 µin/in-°F | ASTM E831 (TMA) |

| Thermal Conductivity | 0.122 W/m-K | 0.85 BTU-in/hr-ft²-°F | |

| Maximum Service Temperature, Air | 171 °C | 340 °F | Continuous Service Without Load |

| Deflection Temperature at 1.8 MPa (264 psi) | 204 °C | 400 °F | ASTM D648 |

| Glass Temperature | 215 °C | 419 °F | ASTM D3418 |

| Flammability, UL94 | V-0 | V-0 | UL94 |

| Descriptive Properties | |||

| Compliance – Canada AG | Not Compliant | ||

| Compliance – Dairy 3A | Not Compliant | ||

| Compliance – FDA | Compliant | ||

| Compliance – NSF | Compliant | ||

| Compliance – USDA | Compliant | ||

| Compliance – USP Class VI | Compliant | ||

| Service in Alcohols | Acceptable | ||

| Service in Aliphatic Hydrocarbons | Limited | ||

| Service in Aromatic Hydrocarbons | Unacceptable | ||

| Service in Chlorinated Solvents | Unacceptable | ||

| Service in Continuous Sunlight | Acceptable | ||

| Service in Ethers | Acceptable | ||

| Service in Inorganic Salt Solutions | Acceptable | ||

| Service in Ketones | Unacceptable | ||

| Service in Steam | Acceptable | ||

| Service in Strong Acids | Unacceptable | ||

| Service in Strong Alkalies | Unacceptable | ||

| Service in Weak Acids | Acceptable | ||

| Service in Weak Alkalies | Acceptable | ||

Recycling Program – Certified Drops

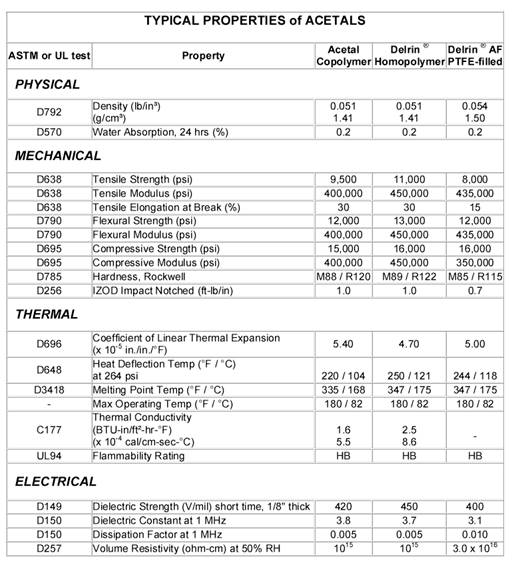

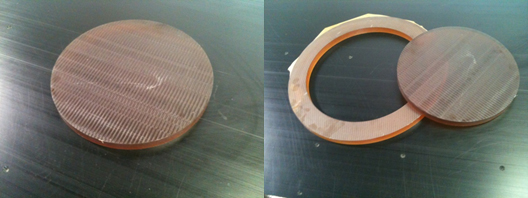

We currently have Delrin drops available. Delrin® acetal resin bridges the gap between metals and ordinary plastics with a unique combination of creep resistance, strength, stiffness, hardness, dimensional stability, toughness, fatigue resistance, solvent and fuel resistance, abrasion resistance, low wear and low friction.

We currently have Delrin drops available. Delrin® acetal resin bridges the gap between metals and ordinary plastics with a unique combination of creep resistance, strength, stiffness, hardness, dimensional stability, toughness, fatigue resistance, solvent and fuel resistance, abrasion resistance, low wear and low friction.