Plastic CNC Machining

Advantages of Custom CNC Machining in Modern Applications

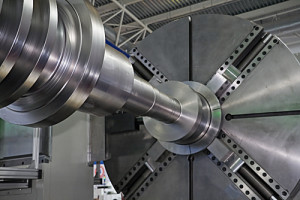

Computer numerical controlled machines, or CNCs, are one of the most utilized tools in the manufacturing industry nowadays. The development of custom CNC machining has been responsible for the production of a lot of parts and products used in many different industries, thanks to the quality and precision that these machines are capable of. Controlled by computers, these machines are capable of handling many different materials. CNC machined plastic, wood, and stone items are common, which is very different from its uses in the past, when it was only used for shaping steel.

Computer numerical controlled machines, or CNCs, are one of the most utilized tools in the manufacturing industry nowadays. The development of custom CNC machining has been responsible for the production of a lot of parts and products used in many different industries, thanks to the quality and precision that these machines are capable of. Controlled by computers, these machines are capable of handling many different materials. CNC machined plastic, wood, and stone items are common, which is very different from its uses in the past, when it was only used for shaping steel.

Custom CNC machining has been available since the 1970s. Up to now, most computers that control the machines use CAD or CAM to determine and direct measurements and parameters for shaping. The use of computers in metal and plastic CNC machining has helped in gradually eliminating the need for manual interference during operations. This helps in numerous ways with allotting more time for a larger volume of work to be handled within a day.

One of the most important innovations in numerical controlled machines is the introduction of CNC machined plastic products. Plastic has been such an important material in various industries over the last few decades that it was only natural for custom CNC machining to incorporate functions for it. CNC machined plastic parts are now common in many products, especially now that plastic parts can be manufactured with such precision and accuracy. Plastic CNC machines are now abundant, as more and more manufacturers of various items are switching to plastic parts for their production.

The use of CNC machines has made it possible for a lot of operations to run with a lot more ease. The quality and precision of these machines allows them to continue with a series of repetitive tasks with pinpoint accuracy. Custom CNC machining has also cut down a significant amount of time with a lot of different operations, which directly contributes to increased productivity. The level of accuracy that these machines possess has also made it possible for certain things that were impossible in the past to be executed nowadays.

CNC machines have definitely become a necessity in many industries today. Many businesses would not have thrived in their respective environments without the presence of such advancements which have helped reshape their entire industry’s landscape.