At Plasteel, we strive to grow with our customers, and that means updgrading to new, cutting-edge equipment. This past year alone, we added an additional 5-Axis Mill, and upgraded another flat-bed router.

MAZAK 5-AXIS MILLING CENTER

VC-500A/5X (X2)

5-AXIS ROBUST AND A HIGHLY REPEATABLE MILL OFFERING MORE PRECISE “CLOSER TO NOMINAL” PRODUCTION PARTS 20” DIAMETER ROTARY WITH 20” TRAVEL IN X, Y, & Z 5-AXIS ABILITIES ELIMINATE ACCUMULATIVE TOLERANCES CLOSER TO DONE-IN-ONE, THE 5-AXIS REDUCES SET-UP TIME, NEED FOR FIXTURING, AND TOOLING, WHICH IMPROVES LEAD TIME DUAL PROBING FOR PART INSPECTION AND MONITORING OF TOOL BLENDS

MAZAK 5-AXIS MILLING CENTER

VARIAXIS C-600

THE AUTOMATION-READY VARIAXIS C-600 SIMULTANEOUS 5-AXIS VERTICAL MACHINING CENTER USES RIGID C-FRAME CONSTRUCTION, A STANDARD 30-TOOL CHANGER, DUAL-SUPPORTED TILTING TABLE AND FAST RAPID TRAVERSE RATES TO REDUCE CYCLE TIMES ON DEMANDING JOBS. IT ACCEPTS A WIDE RANGE OF SPINDLES, INCLUDING HIGH-SPEED AND HIGH-TORQUE OPTIONS, TO PRODUCE A WIDE RANGE OF PARTS FROM STEEL AND NON-FERROUS METALS. ITS MAZATROL SMOOTHAI CNC ADDS EFFICIENCY AND VALUE, WITH A WIDE VARIETY OF ADVANCED PROGRAMMING FUNCTIONS FOR COMPLETE EASE OF USE AND REPEATABLE HIGH-ACCURACY PERFORMANCE.

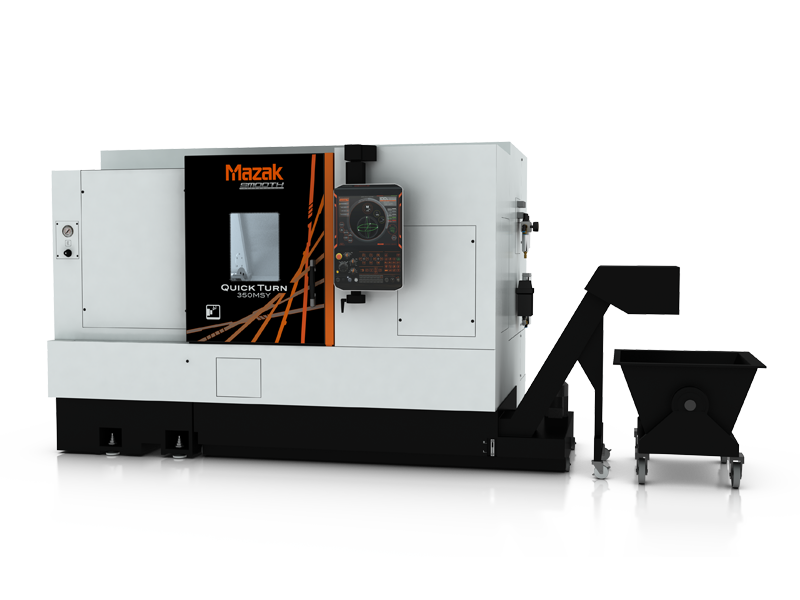

MAZAK TURNING CENTER

QUICK TURN 350MY

RIGID MACHINE WITH 40 H.P. AND TORQUE IDEAL FOR DIFFICULT TO MACHINE AEROSPACE MATERIALS OFFSET CAPABILITIES IN 10 MILLIONTHS 29” GAP BED LATH IS IDEAL FOR LARGER PARTS 15” CHUCK WITH 4”THROUGH SPINDLE LEADING TO LESS RAW MATERIAL WASTE 18” PIE JAWS TO REDUCE PART DEFORMATION FULL PROGRAMMABLE TAIL STOCK, FULL PROGRAMMABLE THRUST

ANDERSON AMERICA CNC ROUTER

STRATOS/NEST (X2)

THE STRATOS MACHINING CENTERS SET A NEW STANDARD IN COST-EFFECTIVE, HIGH-SPEED CNC MACHINING. CNC CONTROLS INCLUDE ETHERNET OPTIONS TO PROVIDE REMOTE TECHNICAL SUPPORT; OPTIONAL C-AXIS AVAILABLE. THE WORKPIECE HOLDING FLEXIBILITY IS PROVIDED BY OPTIONAL CLAMPING, GRID OR MANIFOLD VACUUM SYSTEMS. THE STRATOS CNC MACHINING CENTER UTILIZES AN INDUSTRY STANDARD G-CODE FOR CONTROL FUNCTIONS THAT ALLOWS EASY INTERFACING WITH ALL MAJOR CAD/CAM SOFTWARE AND INDUSTRY STANDARD SOLID MODELING SOFTWARE PACKAGES. ADDITIONAL OPTIONS INCLUDE WORKPIECE DIMENSION PROBING, BOTH SINGLE AND DUAL ZONE CAPABILITIES AND CUSTOM CONFIGURATIONS UPON REQUEST.